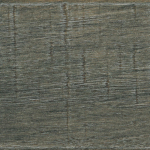

Reactive Stain Anthrazit on oak — Reactive stains, also named chemical stains, are reacting with tanning agent of wood. This results unique optics on every piece of wood.

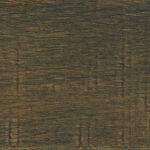

Reactive Stain Caramel on oak — Reactive stains, also named chemical stains, are reacting with tanning agent of wood. This results unique optics on every piece of wood.

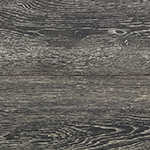

Reactive Stain Cherry on oak — Reactive stains, also named chemical stains, are reacting with tanning agent of wood. This results unique optics on every piece of wood.

Reactive Stain Grey Gold Pearl on oak — Reactive stains, also named chemical stains, are reacting with tanning agent of wood. This results unique optics on every piece of wood.

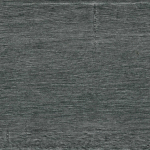

Reactive Stain Natural Grey on oak — Reactive stains, also named chemical stains, are reacting with tanning agent of wood. This results unique optics on every piece of wood.

Reactive Stain Old Grey on oak — Reactive stains, also named chemical stains, are reacting with tanning agent of wood. This results unique optics on every piece of wood.

Reactive Stain Pearl Cherry on oak — Reactive stains, also named chemical stains, are reacting with tanning agent of wood. This results unique optics on every piece of wood.

Reactive Stain Tabac Light on oak — Reactive stains, also named chemical stains, are reacting with tanning agent of wood. This results unique optics on every piece of wood.

Reactive Stain Tundra on oak — Reactive stains, also named chemical stains, are reacting with tanning agent of wood. This results unique optics on every piece of wood.

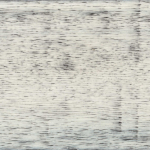

Reactive Stain White on oak — Reactive stains, also named chemical stains, are reacting with tanning agent of wood. This results unique optics on every piece of wood.

High Solid Oil Wax - milk-coffee — Coloured oxidative drying oils for creating an individual touch - also available in many other colours

High Solid Oil Wax - middle-brown — Coloured oxidative drying oils for creating an individual touch - also available in many other colours

High Solid Oil Wax - chocolate brown — Coloured oxidative drying oils for creating an individual touch - also available in many other colours

Solvent Stain grey — Coloured primers could simplify the process – adhesion promoter and colouring in one step

Stain Dark Sky — Coloured primers could simplify the process – adhesion promoter and colouring in one step

Stain Dust grey — Coloured primers could simplify the process – adhesion promoter and colouring in one step

Stain Light grey — Coloured primers could simplify the process – adhesion promoter and colouring in one step

Raw Wood Effekt — Coloured primers could simplify the process – adhesion promoter and colouring in one step

Chocolate brown — Coloured primers could simplify the process – adhesion promoter and colouring in one step

Snow — Coloured primers could simplify the process – adhesion promoter and colouring in one step

Platinum — Coloured primers could simplify the process – adhesion promoter and colouring in one step

Silver — Coloured primers could simplify the process – adhesion promoter and colouring in one step

Rock fall — Coloured primers could simplify the process – adhesion promoter and colouring in one step

Cortem — Coloured primers could simplify the process – adhesion promoter and colouring in one step

Titanum — Coloured primers could simplify the process – adhesion promoter and colouring in one step

Panther — Coloured primers could simplify the process – adhesion promoter and colouring in one step

Sapwood stain - sample 1 — Egalizing strong looking colour differences in wood

Pore liming white — Pore liming would be applied on medium strong structured wood, which is able to receive it. A sealing of limed pores is necessary.

Pore white on dark grey — Pore liming would be applied on medium strong structured wood, which is able to receive it. A sealing of limed pores is necessary.

Pore white on light grey — Pore liming would be applied on medium strong structured wood, which is able to receive it. A sealing of limed pores is necessary.

Multi camouflage — Multi-layer effects combine different effect technologies to reach unique optical results.

Multi dark dust on white — Multi-layer effects combine different effect technologies to reach unique optical results.

Multi Smoke grey on white — Multi-layer effects combine different effect technologies to reach unique optical results.

Multi vintage white — Multi-layer effects combine different effect technologies to reach unique optical results.

Grey effect 1 — One of many possilbe grey effects - everything is possible!

Grey effect 2 — One of many possilbe grey effects - everything is possible!

Grey effect 3 — One of many possilbe grey effects - everything is possible!

Grey effect 4 — One of many possilbe grey effects - everything is possible!

Grey effect 5 — One of many possilbe grey effects - everything is possible!

Grey effect 6 — One of many possilbe grey effects - everything is possible!

Grey effect 7 — One of many possilbe grey effects - everything is possible!

Grey effect 8 — One of many possilbe grey effects - everything is possible!

Grey effect 9 — One of many possilbe grey effects - everything is possible!

Raw Wood Effekt — Optics like a natural piece of oak - Protected like under glass